by admin | Mar 21, 2018 | LTC Roll Blog

Manufacturing is an ever-changing industry. Therefore, being able to adapt and customize products as the client needs is priceless. Tubular technology is one of the ways we aim to keep our clients happy. Due to tubular manufacturing, we have the ability to make custom pieces that perfectly fit the needs and expectations of our clients. And with new equipment as far as tubular design is concerned the possibilities are endless. What is Tubular Manufacturing Tubular manufacturing is creating tubing and tubular parts specific to the needs of our client. Gone are the days of only being able to buy generic tubing. With tubular manufacturing, we create tubes of all different shapes, sizes, and materials. Varying forms are now a possibility. Imagine tubes that are round, square, ovular, multi-sided, triangular or any other custom shape. You name it, we can make it. Best of all, we use the best materials to form them. These include durable materials such as Martensite, Aluminum, and CRS. In fact, round tubes are no longer your only option. Technology has allowed us to become more creative and better answer our clients’ specific needs. New Technology Just recently, we acquired two, especially relevant new pieces of equipment that are making our tubular manufacturing even better. The first of these new machines is a 3D fiber laser cutting machine. This machine allows easy cutting of curved surfaces. First of all, the laser optimizes our precision cutting on your custom tubing, and even reduces mold investment. It shortens the development cycle and improves efficiency, repeatability, and precision; which is not only good news for us, but also for...

by admin | Mar 7, 2018 | LTC Roll Blog

When it comes to considering your career, the available options seem limitless. However, there is one field you should not ignore. Manufacturing is a robust industry that continually needs more people. Unfortunately, this field is not as popular as it once was; yet it still remains a crucial industry within our communities. It’s also a varied industry with positions open for different talents. For this reason, a career in manufacturing opens the doors to numerous possibilities. There is a Need The U.S. Bureau of Labor Statistics released a document in 2014 stating there were 264,000 open jobs in manufacturing. That is a staggering number of available jobs that need filling. The Bureau believes that number will only increase as the years pass, and those currently working in manufacturing retire. As more young people are pursuing college degrees for careers in different industries, the number of available manufacturing jobs will only increase. However, fewer people are beginning their careers in this industry. As a result, it leaves more and more jobs available. You could fill a vital role in your community by starting your career in manufacturing. Avoid College Debt Today, everyone agrees that college is expensive; it’s a massive downfall of four-year universities. More and more college students are graduating with massive amounts of student debt with no way to pay it all back. Thankfully, most manufacturing jobs don’t require a four-year degree. Instead, you would take a few skills classes, start in an entry-level position, and learn as you go. By avoiding the debt that usually comes with a four-year degree, you can save money faster. Plus, with...

by admin | Feb 21, 2018 | LTC Roll Blog

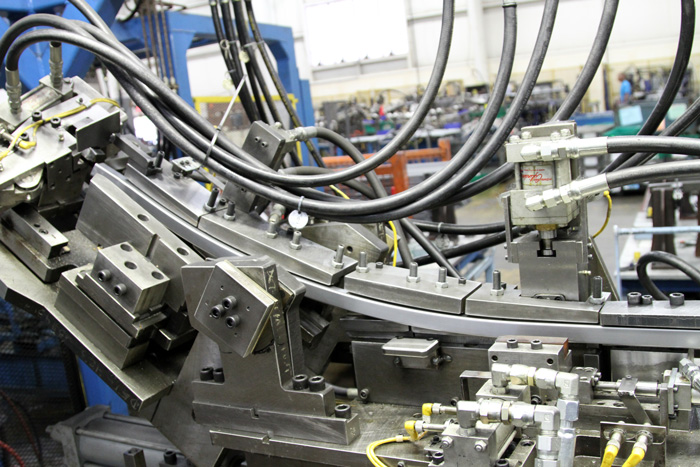

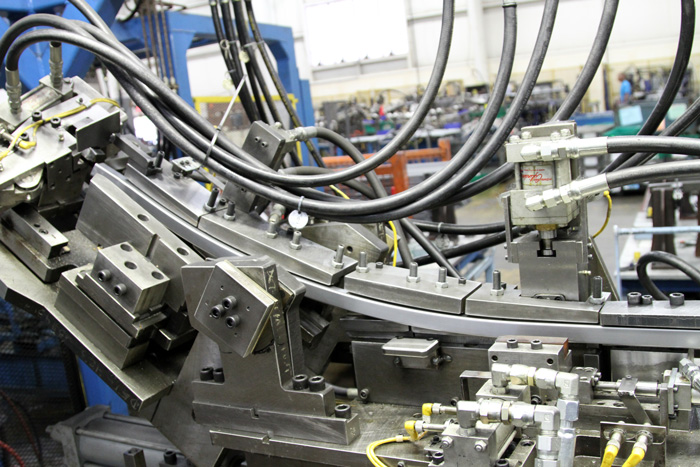

Stretch bending is a very intricate process that has evolved in many ways over the years. This process is vital to the manufacturing of parts, changing it completely. Surprisingly, many people are unaware of the evolution of this manufacturing process through the years. In this article, you will learn the history of stretch bending in manufacturing. What Is Stretch Bending? Stretch bending is part of metal forming where the metal is bent or “stretched” to create perfectly shaped automotive parts. A machine called a stretch press usually performs this process, shaping multiple different types of metal. When used in manufacturing, stretch bending helps to create automotive parts. These parts are often stronger as well as lighter than ever before, as a result of using very strong materials and working with higher quality machines. As an associate works the sheet of metal through the machine, it strengthens the metal, helping it to keep the specific shape needed. This process continues to make a huge impact on the manufacturing world. How Stretch Bending Has Changed Manufacturing Even though the manufacturing world evolves and changes in small ways, the main process always stays the same. Not only does the process work; it works well. There are many ways stretch bending has affected manufacturing. Some of the main ways include the following: Better Efficiency- When using the stretch bending process in manufacturing, it leaves less room for error, which is a direct result of a machine doing the work. Every minute an associate uses these stretch presses, they create another amazing auto part. Reduced Labor Cost- As stated above, the work is being done by...

by admin | Feb 7, 2018 | LTC Roll Blog

The art of roll forming and stamping is an interesting process that dates all the way back to 4000BC. It originated as the process known as forging in Egypt, Mesopotamia, and the Mediterranean area. In the beginning, it was just gold and silver that was forged to make jewelry and weapons. Iron only became the staple for weapons, parts, and tools in 700BC. Fast-forward to the present where the roll forming and stamping process uses many different materials. Today, leading companies that work in the field of automotive metal forming continue to perfect these processes. Automotive metal forming is a vital aspect of metal forming. Keep reading to learn more about this fascinating industry and the benefits it offers. What Is Automotive Metal Forming Automotive metal forming is the process of bending or shaping metal into a specific shape to create automotive parts. Metal can undergo something called plastic deformation. This means that the metal can take any shape you could imagine. Roll forming uses force to change the shape of the metal. Stamping, but, is a little different. This process incorporates a machine called a stamping press. This machine uses dies to cut metal into the shape itself. Both of these processes have their advantages when creating different automotive parts. This process creates many parts ranging from bumper beams and door frames, to seat tracks, cross sills, and brackets. Without automotive metal forming, building cars would be a difficult process; they might not even exist. For cars to work, we need parts that are contoured, and that can only happen with roll forming and stamping. Benefits of Roll Forming and Stamping There...

by admin | Jan 17, 2018 | LTC Roll Blog

Assembly lines have changed dramatically over the past one hundred years. New techniques and assembly styles allow for speedy and flexible production. Certain new methods address some of the most serious assembly line flaws by protecting employees. Others allow both efficient production and options for customization and partial assembly. Here are the four most common types of assembly lines still in use today. Classic A classic assembly line is the sort of manufacturing process early car manufacturers like Ford made memorable. This type of assembly line uses a number of steps, performed by different workers, to create a single product. That product is usually large and/or complex. Regardless of size or complexity, however, each product is essentially identical. Again, cars are a great example. A car is not a simple thing to build, but every car with the same make, model, and year feature all the same parts in the same places. Automated An automated assembly system might look a lot like a classic one, but it features one critical difference. There are fewer humans and more machines. Machines governed by computers almost entirely staff today’s automated systems. Many manufacturers adopted this model over the past decade or two. In theory, it reduces long-term costs, and it certainly cuts down the likelihood of human errors. Most of these systems still follow classic procedures, however, and many build similar products. One great advantage automated systems have over human labor is the ability to handle hazardous materials. The age of radium girls is over. Those kinds of jobs, now go to machines. Intermittent Unlike the previous two assembly line types, intermittent...

by admin | Jan 3, 2018 | LTC Roll Blog

Modern manufacturing has made metal products available to all kinds of customers. This is still a fairly recent development, though. Metal manufacturing today owes a lot to the inventiveness of traditional metalworkers and blacksmiths. The First Metalworkers Originally, all metalwork products were unique, hand-worked items. Softer metals could be melted and poured into forms. The first evidence of metal work appears in ancient Palestine and surrounding Middle Eastern regions. These early craftsmen worked with very soft metals, such as gold, silver, and copper. Since craftspeople were still learning how to remove ore from rocks, metalworking was relatively rare, and the metals favored by early craftsmen often appear in large, unified quantities. Gold, for instance, may appear in relatively pure ‘nuggets.’ As harder metals like iron became more readily available, blacksmiths became the default metalworkers of their communities. Since even their hot hearths couldn’t keep hard metals soft for long, blacksmiths developed stage-oriented production methods that focused on shaping hard metal in stages. A blacksmith heated the metal, worked it briefly, returned the metal to the heat, and continued in this rhythm until he finished creating the product. One of the greatest problems for metalworkers was heat. Many specialized tools, including bellows, were invented to spike a fire’s heat so it could adequately soften hard metals. There are still plenty of blacksmiths around today, although they typically make artisan products that are far more expensive than mass-produced options. Improving Metal Manufacturing leaders today directly link the evolution of metalworking with the ability of individuals to not just shape but also mix metals. Most of the metal we use today is not a...