by admin | Dec 17, 2018 | LTC Roll Blog

Autonomous vehicles are the result of modern technological inventions and are considered the future of the automotive industry. These driverless vehicles use various kinds of technologies, such as GPS-sensing knowledge for navigation and sensors to avoid collisions. Their advanced technology dashboards are pretty cool and display information that we don’t see in regular cars. Even though they are a sensation around the world, the success of autonomous vehicles will largely depend on how safe the public perceives them to be. Becoming a Reality Even though driverless cars often appeared in science-fiction movies, they are becoming a reality sooner than we thought. The automotive industry is already taking this technological revolution into account and preparing for the production of parts and technology needed for autonomous vehicles. Additionally, there is money pouring in for more research to improve the technology behind these vehicles. Challenges to Face Although we are embracing the new set of autonomous vehicles and investing in technology, there are still some challenges to overcome before our roads are flooded with driverless vehicles. Manufacturers must tackle a variety of technical challenges, and humans have to be able to accept them without concern. Among other challenges, traffic infrastructure needs to take into account the new set of vehicles and their trajectory to ensure proper safety on the road. We still have a long way to go for an infrastructure that can completely embrace autonomous vehicles. Need for Standardization Developers of autonomous vehicles are pursuing different strategies and technologies, and they are all making different claims. This makes it harder to compare two sets of autonomous vehicles as far as safety...

by admin | Nov 30, 2018 | LTC Roll Blog

With the newly announced sweeping tariffs on steel and aluminum, the world’s economy is in for a big upheaval. Many manufactured goods in the United States of America depend on steel and aluminum. With the changes in tariffs and subsequent international reactions, the prices of manufactured goods could change significantly. Increased Tariffs The reason for the change in tariffs is to promote the usage of domestic steel and aluminum and revive this industry. Steel and aluminum have been one of the top imports for the United States. Steel made in another country and shipped to the United States will be now subject to a 25% tax. Imported aluminum will be taxed 10% at the US border. While this promotes the domestic steel industry, the prices of goods that use steel and aluminum can drastically change. Increase in Prices of Manufactured Goods The whole idea of increasing these tariffs is so that it would become profitable to make more steel and aluminum domestically. Theoretically, this would give rise to more jobs and help the US economy. However, the automotive industry relies heavily on steel. Additionally, a lot of everyday products use steel and aluminum. Manufacturers will have to incur additional costs in order to make changes to their steel suppliers and possibly make operational and process changes. Eventually, this will cause an increase in the prices of manufactured goods. Those price increases are then going to be passed on to consumers. World Economy Some of the top countries that send steel and aluminum to the United States of America are Canada, Brazil, South Korea,...

by admin | Nov 12, 2018 | LTC Roll Blog

Quality of products is the most important aspect for all manufacturers. With that in mind, the International Automotive Task Force (IATF) develops standards of quality control for the automotive industry. IATF 16949 is an evolutionary standard that replaces the ISO/TS 16949 standard. IATF 16949 adds a more risk-based approach to automotive quality assurance. It is progressive and takes a more preventative approach so that manufacturers can prevent versus detect quality defects. OEM suppliers have to comply with the new requirements and go through audits in order to be certified. More Accountability with KPIs A key focus area for IATF 16949 is management accountability for key performance indicators (KPIs). KPIs are great tools that help you track your ongoing progress towards your goals. This new standard requires that companies not only set targets but must also provide details on action plans if they can’t meet them. Documenting these procedures is part of the ongoing process for all manufacturers. Going forward during audits, auditors will be reviewing KPIs and how the companies are tracking as well as reviewing them. Risk Management Risk management for OEM suppliers is another focus area of IATF 16949. As part of this new standard compliance, OEM suppliers must have proper checks for product safety. They will also need to provide adequate employee training which will mitigate risk. Training details will be verified during audits as well. The idea behind these changes is that when you have proper risk management procedures identified in the beginning, you can prevent defects earlier in the cycle. Producing High Quality LTC Roll and Engineering...

by admin | Oct 19, 2018 | LTC Roll Blog

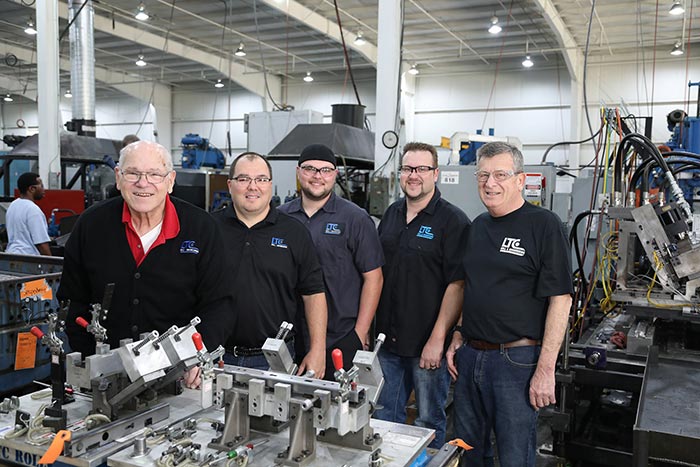

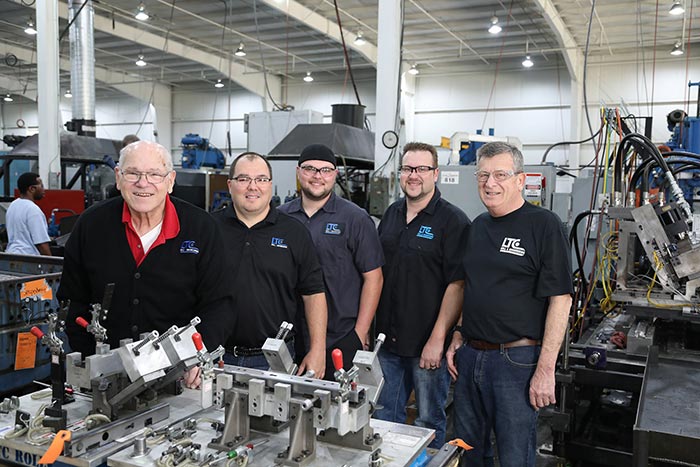

Manufacturing Day is an annual event that is held on the first Friday in October and inspires innovation in modern manufacturing technologies. This year, Manufacturing Day was held on October 5 and was supported by manufacturers around the country. The celebration provided opportunities for students, job seekers, and other community members to attend open houses and tour different plants as well as attend insightful presentations. Inspiring the young minds Since manufacturing is one of the top drivers of economic prosperity, it needs to be encouraged among young children as a viable career path. Manufacturing Day gives us the opportunity to bring about increased awareness and inspire the next generation. We can address any misconceptions about manufacturing as a career by opening our doors and showcasing our plants and processes. Collectively we can build a steady pipeline of qualified and diversified talent for years to come. Innovation is the need of the day Manufacturing has come a long way throughout the last century. Mass production has grown, and automation has allowed manufacturing tasks to become more efficient in recent times. With increasing demands of manufactured goods, innovation is the need of the day. We need young and curious minds to join the manufacturing workforce and discover and innovate from the ground up. Manufacturing is a combination of problem-solving, innovation and consistency. With so many parts manufactured every day, quality and consistency are of the utmost importance. Innovation helps with maintaining quality and provides consistency in every manufactured piece. We take pride in our Manufacturing Process LTC Roll and Engineering has a longstanding reputation for excellent manufacturing in the automotive industry....

by admin | Jul 18, 2018 | LTC Roll Blog

If you haven’t experienced a manufacturing assembly floor before it can be a place shrouded in mystery. Is it a place filled with metal and big robots doing all the work? Are they full of sparks from welding? Are they organized or kind of a mess? Movies and pictures don’t do these places justice. The manufacturing assembly floor is where so many of the things we rely on daily are put together and readied for us. We’ve put together some information to help you understand what the assembly floor looks like. Welding Welding is a major part of manufacturing and especially assembling. The big and small pieces of metal that need to fit and stay together to create a finished product need a type of glue to do the job. Welding is the glue that holds all of the pieces together. And so, in a welding section of an assembly line, you are likely to see a lot of sparks. You would also likely hear the equipment warming and joining the metal pieces together. There are three main types of welding that we at LTC Roll and Engineering use, and you can read more about them here. Tools As you could have guessed, there are countless tools on the assembly floor. From welding equipment to grease guns, compression tools, and drills, assembly floors have more tools on them than you could count! Because the assembly process is so detailed and diverse depending on what is being assembled, different tools are necessary. You will see it all on the floor. Both high powered and hand powered tools are available on...

by admin | Jul 4, 2018 | LTC Roll Blog

There are many benefits of being in manufacturing for over 50 years. However, the most significant is that LTC Roll and Engineering possesses the experience needed to make designs work. If a custom design requires special equipment and tooling to complete, we have the ability to make them, even if the tools required are not available. There are many benefits to being able to develop and create our own custom tooling. Primarily, our customers are given more freedom in the designs they want to create. However, it also gives us more freedom when prototyping and manufacturing those designs. Here are a few impressive reasons why LTC Roll and Engineering creates custom tooling in their manufacturing practices. Custom Created Tools Over the years we have developed a number of tools that have helped us enhance and expedite our manufacturing process. On behalf of our customers and their products, we build a wide range of tools. For instance, we have built turnkey production lines, enabling us to take a design and move it from development to completion quickly. We have also built many other tools including, cutoff, pre-pierced, roll form, and secondary forming dies. All of these tools have given us the freedom to provide the end results and products our customers are looking for. Design Freedom Our customers have greater freedom when it comes to designing their products because they know we can deliver. If we don’t currently have the tools required to get the job done, we will customize tooling to satisfy the need. Our skilled associates allow us to also work at an expedited rate. Even if we are building out...