Many assume that because manufacturing is an older industry that focuses on building bigger pieces, that it also lacks a sense of finesse. However, there is more to manufacturing than just slapping together large pieces of metal. A great deal of thought, process, and design go into manufacturing. Moreover, an important stage of that process is prototyping. Prototyping involves a lot more than simply making a sample of a product. There are important reasons why prototyping happens before a design goes into production. Let’s look closely at why prototyping is so crucial to the manufacturing process.

Proof Designs

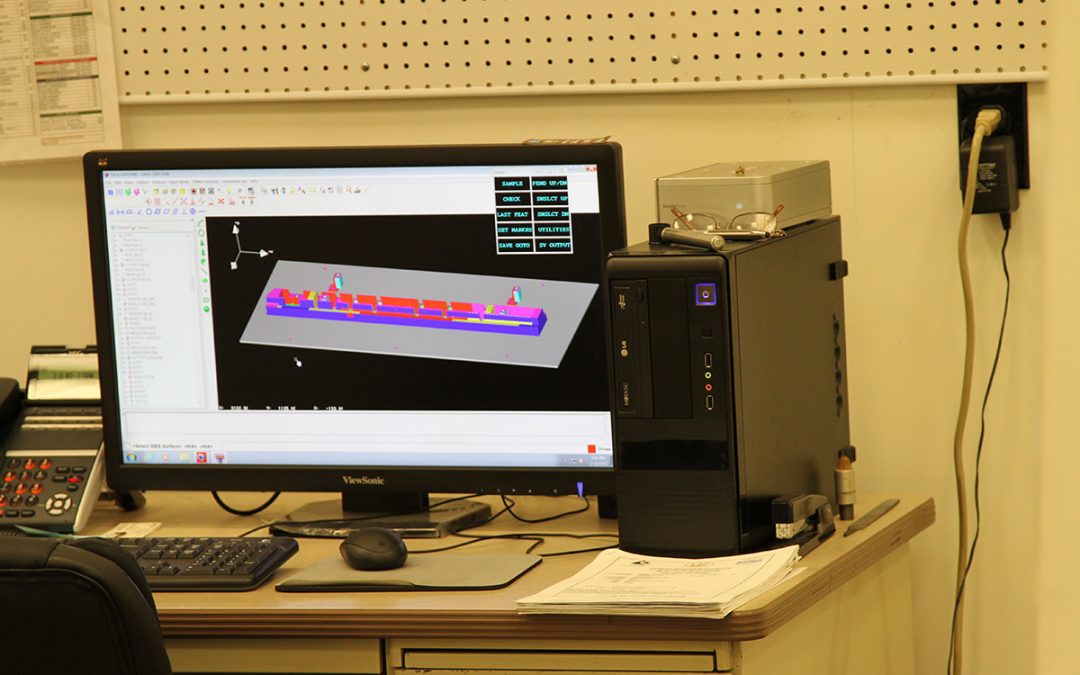

A design will never be perfect the first time through, and so the proofing process is needed. A prototype can be looked over and evaluated to get a better understanding of the specific design. At this stage, you can tweak things and alter the design to optimize it. Just as you would look at a spreadsheet or press release before sending it out, creating a prototype of your design is the last look over. Once the design meets both parties’ approval, the design can go into production with the security that it is optimized.

Identify Defects

Whether a client or the manufacturing company come up with the design, there could be unforeseeable problems on the page. By producing a prototype, both parties can visualize the final product. If there are any defects or potential problems, you can correct them before final production begins. Evaluation at this stage is critical to producing the highest quality finished product. It is also easier to find issues when you have a physical copy of what you are trying to build. What looked good on paper could be less than ideal in actuality.

Save Money

Mistakes in any industry can be costly. However, in manufacturing, it can cause the manufacturing costs to skyrocket. Prototyping ensures that the best defect free design goes into production. It ensures that you produce the final product with consistency. It also cuts down the production time, as the defects and edits have already been taken care of in the prototype stage. Once production begins, it will run through saving time and money overall in the end.

Manufacturing is a hands-on and detailed process. Machinery does a lot of the heavy lifting, but it requires the human details to take a design from conception to mass production. Prototyping is one of the most critical pieces of the manufacturing puzzle. For LTC Roll and Engineering, it ensures that we are producing the best possible products. We work hard in all stages of the process to optimize the design and production time. Prototyping ensures we are accomplishing our goal of producing the highest quality product we can. For more information on how we can help you bring your designs to life give us a call, (586) 465-1023.