Decades of Proven Roll Forming Excellence

Today, roll formed parts from LTC appear in every single full sized truck, SUV’s and automobiles from the world’s largest automotive manufacturer. Our proprietary processes, advanced materials knowledge, and exhaustive subject matter expertise enable us to produce parts that are stronger, lighter, more durable, and more cost-effective, providing outstanding value to our customers and end users.

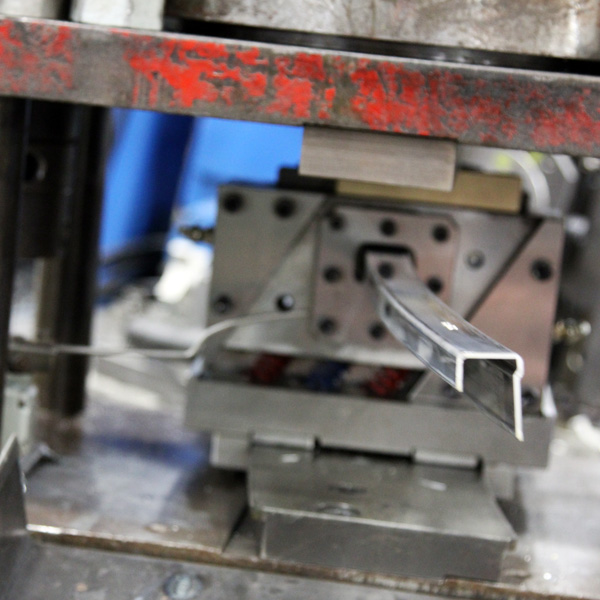

LTC has pioneered the tools and processes that enable successful roll forming of today’s advanced high-strength, lightweight metals. Our engineers work closely with suppliers and manufacturers to conceptualize, quality test, and refine the processes needed to successfully transform groundbreaking martensite aluminum, steel, and alloy formulations into reliable, durable production parts. Our expertise helps our clients to produce new generations of vehicles that are lighter, safer, and more durable – often while reducing overall costs.

We have also developed expertise with roll forming techniques utilizing in-line laser welding. We are one of very few roll forming companies to offer this capability plus it offers significant cost and time savings for our customers.

LTC is big enough to do whatever needs to be done and perceptive enough to rapidly adapt to change. Our sophisticated, demanding customers know that they can count on LTC to deliver quality and value with every contract and with every part they produce. In the pursuit of vehicle excellence we are the customers trusted partner for quality roll form tooling and roll formed parts.

Capabilities

- Over 60 Roll Form Lines

- Tishken, Yoder, and RLM equipment

- 8-36 Pass Capability

- 1” – 3” Spindle

- Continuous and Compound Sweep

- Uncoilers, Pre-Notch and Cutoff Presses

- In-Line Laser Welding

- Induction welding/mig/tig

Steel Types

- Aluminum

- CRS/HRS

- Dual Phase

- Martensite 980-1700 mpa

- HSLA

- Stainless Steel 300 400 Series

- Painted Material

When it comes to vehicles, some of the parts you don’t usually think about can matter the most. LTC has worked with leading OEMS, engineers, and metallurgists to figure out how to make rocker panels stronger, lighter, and more durable; which contributes to stronger, lighter, more durable vehicles.

We were one of the first companies in our industry to manufacture a roll-formed Martensite rocker panel. Today, our strong, lightweight martensite rocker panels go into four different vehicles for one major auto manufacturer. We fabricate and assemble the full assemblies in-house so that they’re ready to go straight into the vehicle the moment they arrive at the factory. Our unique approach and proprietary processes have increased the part’s strength while cutting weight, waste, and tooling costs. Our engineers figured out how to change from cost-intensive hot stamping in Martensite fabrication, dispensing with the need for special presses and tools. This increased the manufacturing process by more than 25%!

LTC’s unique approach to rocker panel manufacturing is readily adaptable to virtually any vehicle size or type, and can afford all drivers and their families the same added safety. And companies are taking notice! On average, our unique approach to rocker panel manufacturing saves our clients between 25% and 40% in both manufacturing time and per-part costs while reducing vehicle weight and boosting efficiency. Even though most drivers probably never see or think about them, they benefit from the added safety that these tough, durable panels provide.